Who’d have ever thought that something as simple as the distributor hold down on the Y would require an article in which to point out some manufacturing differences on them? But differences there are.

For the first eight years of Ford Y production, the Y used a simple stamped steel piece to keep the distributor snugged in place. If you have dealt with these over a period of time, you have found some of these that became distorted to the point that they would not keep the distributor tight. It’s the distorted distributor hold downs that make it difficult to maintain the ignition timing on some engines as the distributors are still able to move or ‘creep’ after being tightened down.

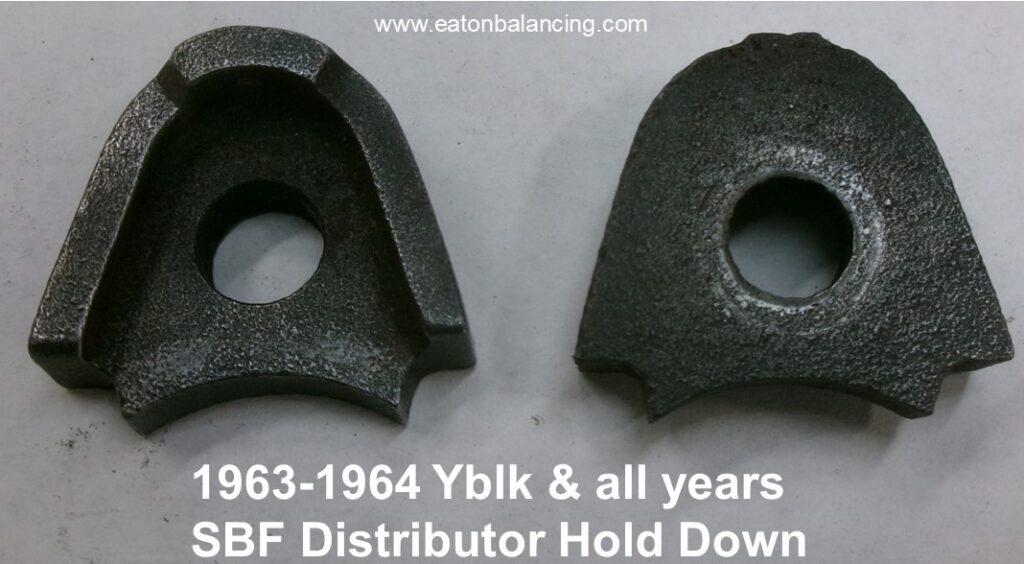

Comes 1963, Ford starts using a cast iron distributor hold down which replaces the older stamp steel units. For the Y, that fixes the problem with the distributors loosening up. From all appearances, that cast iron distributor hold down was originally developed for the small block Ford engines and some engineer had an Ah ha moment and applied it to the current production of Ford Y engines still being used in the pickups and larger trucks.

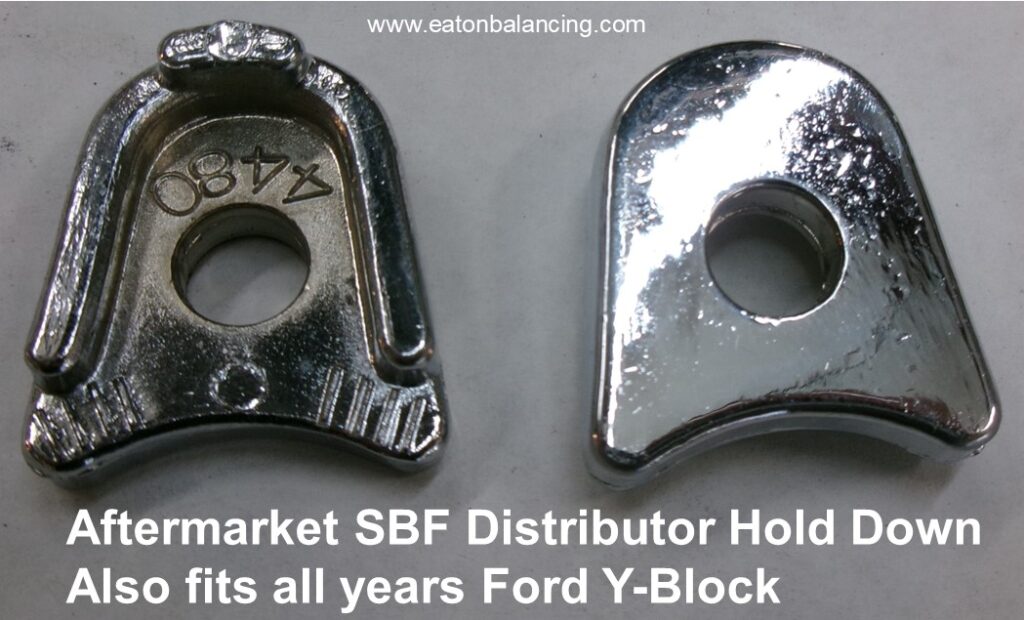

The aftermarket hold downs for the SBF, while still being cast, also have some ribs or ‘teeth’ to help further hold the distributor in place.

So now when I do a Y build, I will instead use one of the small block Ford ‘iron’ distributor hold downs to eliminate the possibility that the distributor might loosen up later. Until next time, happy Y motoring. Ted Eaton

Note: Originally written to be published in The Y-Block Magazine, Issue #180. The discontinuation of that publication did keep that from happening. Ted Eaton.