When the Ford and Mercury Y-Block (FYB) engines were introduced in 1953 for the 1954 model year, the oil pumps being used on those first models incorporated the same pump that was already being used on the Lincoln Y-Block (LYB) engines. The Lincoln engines using that oil pump were introduced in 1951 for the 1952 model year offerings. That pump incorporated a cast iron housing with a pair of side-by-side gears and is known as a spur gear design oil pump.

When originally introduced for the Lincoln engines, the oil pump drive was slotted on both ends. When needing an oil pump for the 1954 model Ford 239 and Mercury 256 engines, the engineering was already in place so the same oil pump with its slotted oil drive was also carried over. With the introduction of the 1955 model engines that also included the 239 and 256 engines for the Ford pickup and truck lines, the oil pump drive was changed to a ¼” hex shaft at both ends. That also included a revision to the distributors so that they too could accommodate the ¼” hex oil pump drive. The hex shaped oil pump shaft design would become the standard design for all pushrod Ford V8 engines from that point forward.

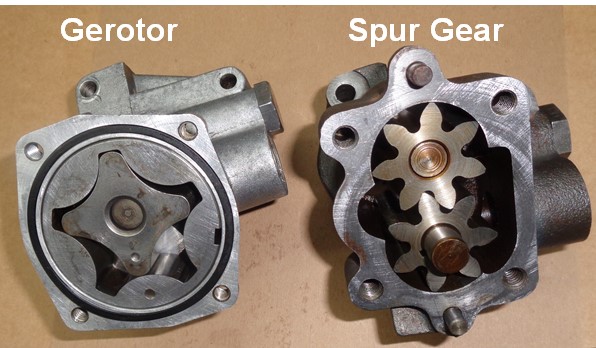

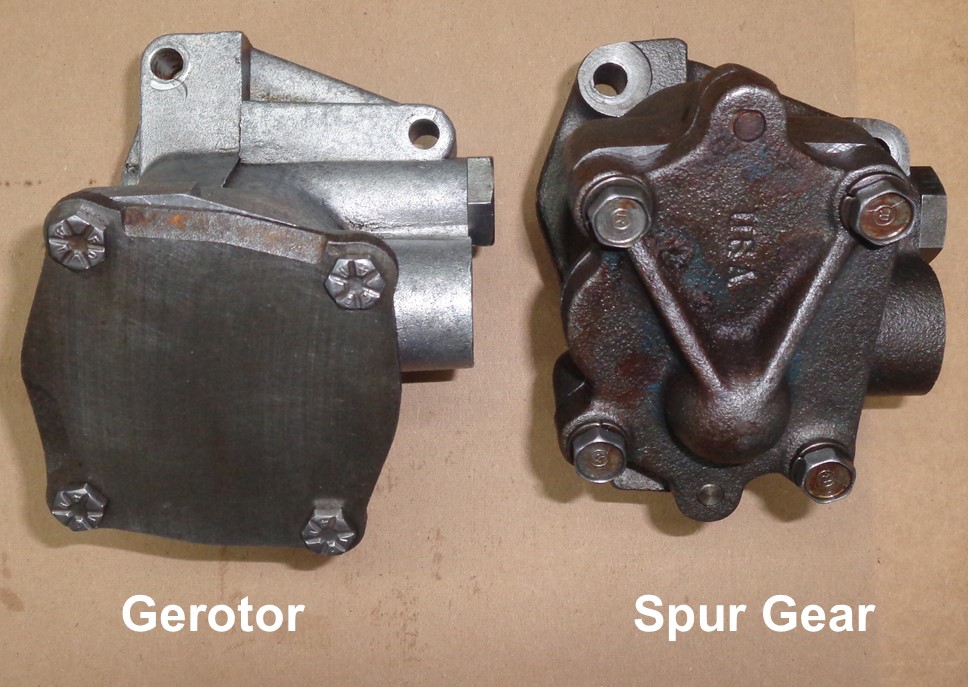

That same spur gear oil pump design would be utilized as the standard oil pump design on the Ford Y engines for the 1954 thru 1956 models. Comes late in the model year for 1956, the ‘new’ gerotor oil pump design was introduced for the 312 engines. For the 1957 model year, all Ford Y V8 engines would use the new gerotor oil pump and that would be the oil pump design used for the remainder of the FYB engine production for vehicles through the 1964 model year. Also of particular note is the gerotor oil pump switched to using an aluminum housing versus the cast iron housing being used on the previous spur gear oil pumps. For service replacements, Ford would issue the aluminum gerotor oil pumps for all 1955 and up Y applications. The 1954 service pump continued being the cast iron spur gear oil pump due to it using the slotted oil pump drive rather than the ¼” hex shaft. The aftermarket however stayed with the previous spur gear oil pump design for all year models and those are continued to be made in the cast iron design to this day. There were a few companies early on making a replacement gerotor oil pump for the Ford Y and those were made with cast iron housings. Those particular pumps are highly sought after even today as they were a very robust design.

The gerotor oil pump design has proven itself over time and is now used by many of the new car manufacturers in their engines. The gerotor design allows for the engine oil to be moved with less energy within the pump thereby reducing the cavitation issues that are prevalent with the spur gear oil pump design. From a mathematical standpoint, the spur gear oil pump for a Ford Y must work six times harder to pump the same amount of oil as a gerotor oil pump. While the spur gear pump design was adequate for the daily driver applications where the engines rarely saw over 4000 rpm for extended periods of time, the gerotor oil pump design raised the bar in that cavitation issues were almost non existent at all rpm levels. There’s no doubt that Fords’ involvement in Nascar racing in the Mid-Fifties forced the development of the gerotor oil pump design. When Ford introduced both the FE and MEL engines in late 1957, both engine designs incorporated the gerotor oil pump designs as standard equipment.

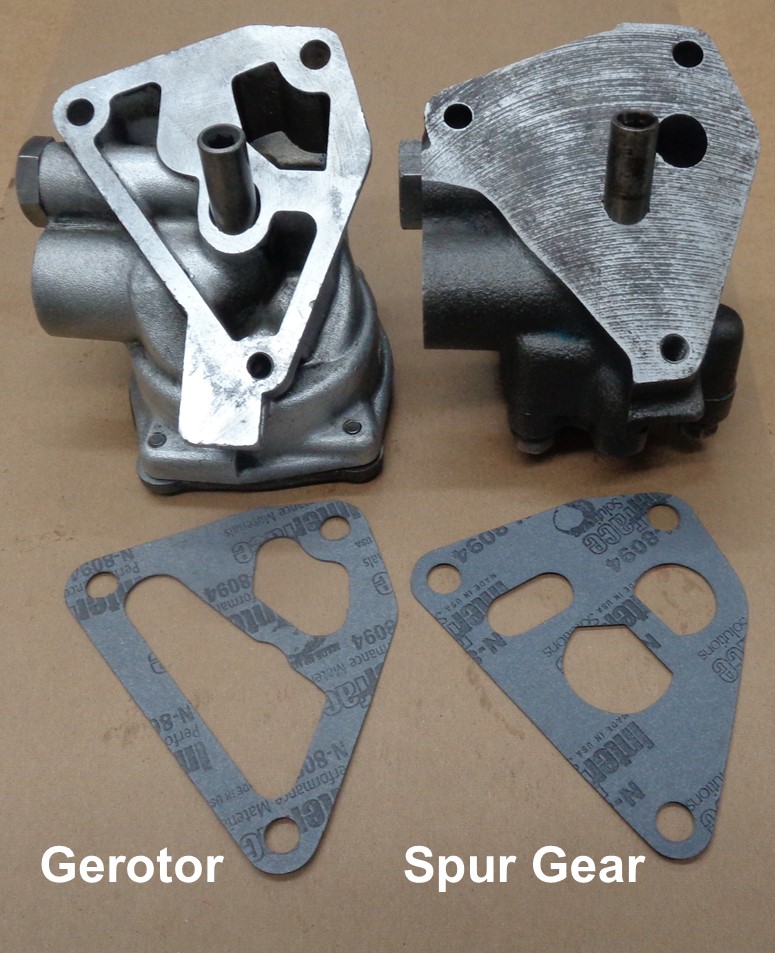

When attempting to identify the two different oil pumps for the Ford Y, the spur gear pump has a cast iron housing along with a cast iron cover that has a single protrusion and a pair of ribs sticking up on that cover. The oem gerotor oil pump on the other hand has an aluminum housing along with a flat steel cover. The aftermarket gerotor oil pumps used a cast iron housing but were otherwise identical to the Ford aluminum housing pumps.

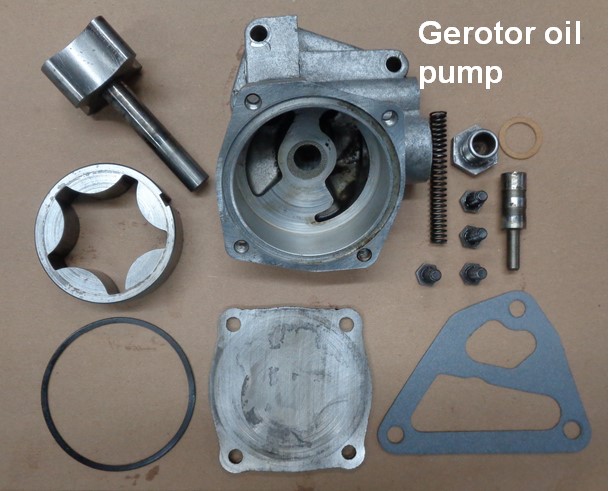

With over five decades elapsing now since the FYB was an engine option in a vehicle, there are literally thousands of those aluminum gerotor pumps still floating around on core engines. Melling does offer a rebuild kit for those pumps with the ordering number being ‘K-56’. The aluminum housings hold

up very well and most are rebuildable. The shop manuals for those vehicles of that era do go into detail on what clearances and specs are used to rebuild those pumps. From a performance standpoint, the gerotor oil pumps are superior to the spur gear oil pump design but if it’s just a daily driver application, the spur gear oil pump is more than adequate for an engine rebuild.

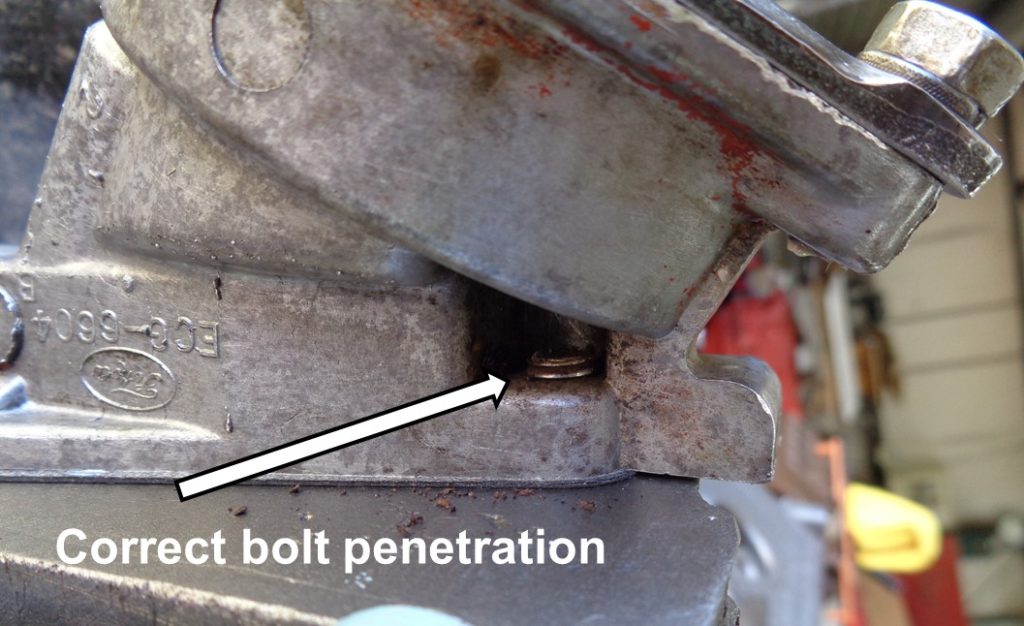

If there is a single flaw or called more aptly ‘an assembly error’ potential with the gerotor oil pump for the Ford Y, it would have to do with the length of the attachment bolts. While the bolt lengths for the Ford Y oil pumps are the same for both the spur gear and the gerotor oil pumps, the length of the attachment bolts being correct do become much more critical for the gerotor style of pump. Bolt lengths are only a problem if not using the original oil pump bolts. But with over half a century now elapsing between now and when these engines were last available new in a vehicle, many of those engines have had at least one rebuild on them and sometimes as many as three. Subsequently some of the original oil pump bolts may have been replaced with non-original bolts and can easily be the incorrect lengths. While being too short is a problem with either style of pump by simply not having enough attachment threads, the bolts being longer than required can create other problems. For the original or replacement spur gear oil pumps, the bolts being too long can just have the bolts bottoming out in their threaded holes thus making the pump not sealing adequately to the block and thereby creating a very noticeable oil leak at that point. The gerotor pump however is a bit trickier when the bolts are as little as a ¼” longer than stock. While two of the bolts will simply bottom out in the block, the attaching bolt that threads into the pump itself will push too far into the aluminum housing and that puts additional pressure on the internal rotors. That creates a situation where the pump can bind up internally thus creating a problem with the distributor gear and/or the pump literally chewing itself up within the aluminum housing.

The correct bolt length for either Ford Y oil pump is 1½” as measured from under the head. A lock washer is required and works in conjunction with that length. For the gerotor oil pumps, an under-head bolt length of 1¾” is just too long and an under-head 2” bolt length can prove to be disastrous in that can destroy an aluminum housing oil pump during the installation phase and not even make it to the run-in phase.

Another issue that comes to the forefront deals with the material used to shim the oil pump relief valve spring. While it is a common practice to shim that spring for an increased oil pressure limit, the use of aluminum or brass material has proven to create chaffed pieces from those materials which can ultimately prevent the oil relief valve from moving freely. While it’s possible that the relief valve can be stuck in an open position, almost all instances of this happening will have the relief valve failing to open thus not limiting the peak oil pressure. The common symptom from this is an abnormally high oil pressure and creates a situation where there is leakage at the oil filter plate gasket. Those oil filter adapter plate gaskets are definitely not happy with 100+ psi oil pressure.

The oil pump to block oil pump gasket is also different for each style of pump. Most full gasket sets for the Ford Y do come with both oil pump gaskets so just match up the appropriate gasket to the pump. While it would appear that either gasket should work with either pump, I did have a situation where there was an oil leak at the oil pump when the incorrect gasket was used.

So there you have it. A brief history on the Ford Y-Block oil pumps and some of the variances and subtle nuances for them. As always, consider this just food for thought. Until next time, happy Y motoring. Ted Eaton.

Previously published in The Y-Block Magazine, Issue #167, Nov/Dec 2021