This is a continuation of a series of articles that goes into the different areas of the engine that can be worked on to increase the power and efficiency of the Ford Y. Keep in mind that many of these also apply to almost all other makes of engines and not just the Ford Y. These topics are in no particular order in regards to their benefits. Some are more beneficial when added or combined with others.

INTAKE MANIFOLDS

And then there’s the intake manifolds. If any cylinder head work is performed that increases the flow capability of those heads, the intake manifold flow must be increased proportionally to get the full benefit out those increased head flow values. On the flip side of this, when using an aftermarket single four barrel intake with the stock Y heads, an increase in top end horsepower can be realized but this can in some instances be at the expense or loss of some low end torque. Careful attention to the head work, valve sizes, camshaft selection, and compression ratios can restore this loss of low-end torque while seeing significant gains in the top end horsepower. A dyno test where nine different modified single four barrel intakes were run on a 352” Y saw the peak horsepower values range between a low of 455 and a high of 502. The intake manifolds in that test included modified Ford iron ECZ-B iron units as well as Blue Thunder and Mummert aluminum intakes. I’ll add that carburetor spacers are also a key factor when dealing with the various intake manifolds.

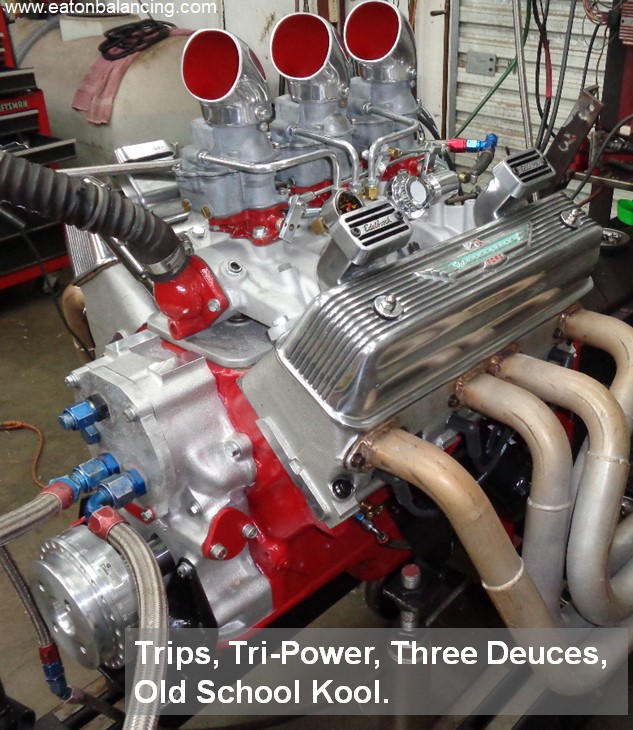

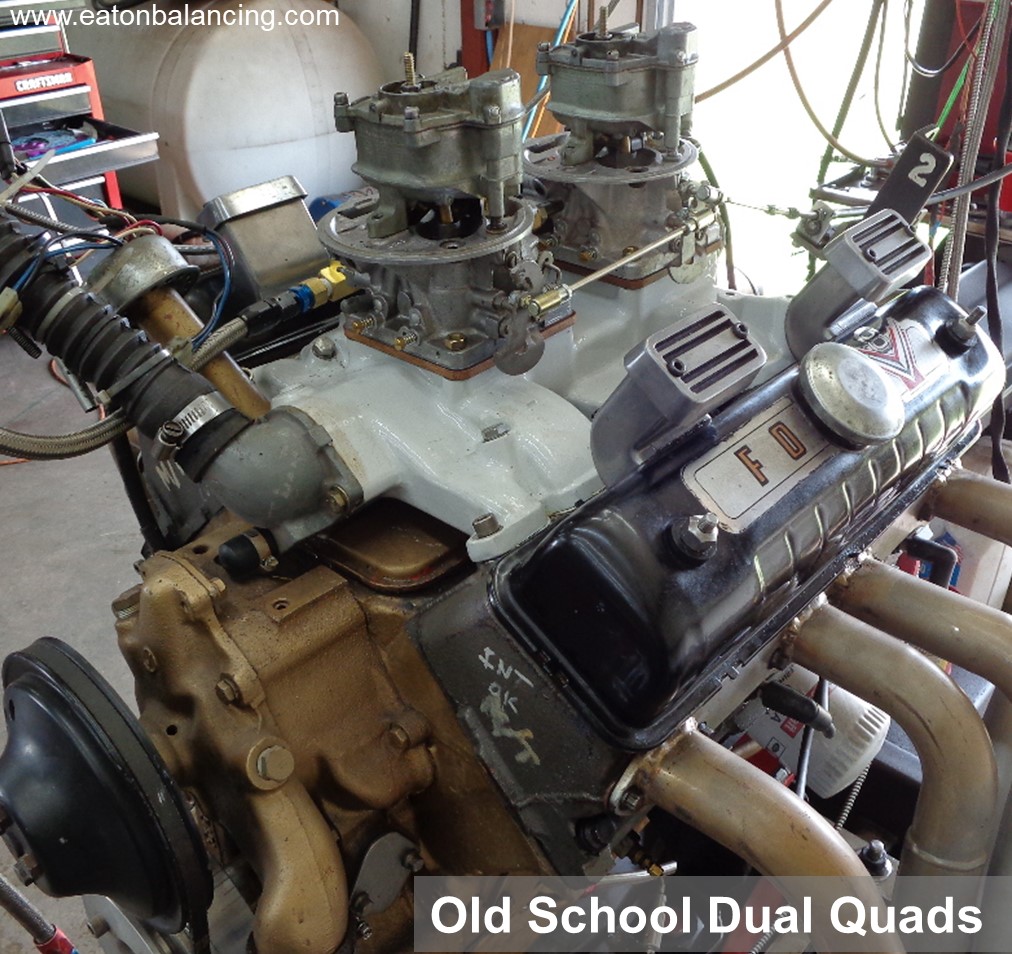

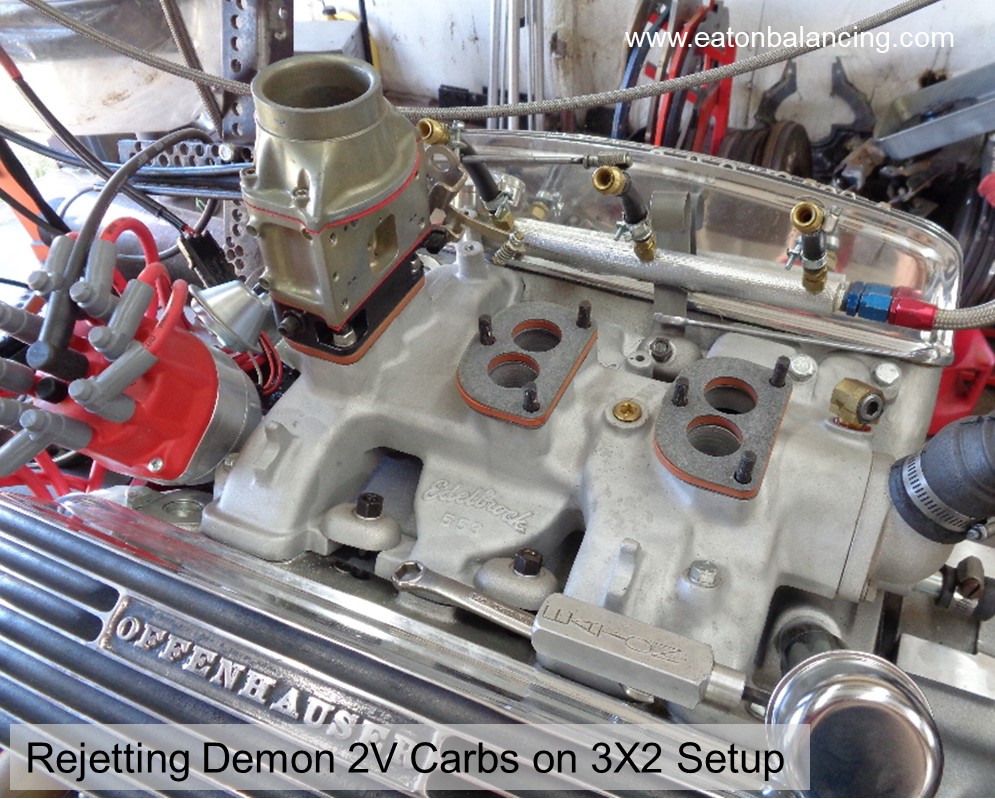

Not to be left out are the multi-carb intake manifolds. There were a multitude of three deuce manifolds produced for the Ford Y by the various manufacturers. Edelbrock, Edmunds, Fenton, Offenhauser, and Weiand are just some of the names that come to mind. Most have been tested and the performance numbers vary depending upon the manufacturer and the carburetors being used. Likewise, there were a number of dual quad manifolds cast for the Y including the factory dual quad manifolds available from Ford both in 1956 and 1957. All those manifolds are expected to work on stock large valve heads but anytime the cubic inches or heads are worked on that increases the air flow requirements for the engine, the manifolds are also required to be modified so that the air flow through the manifold exceeds the requirements for the heads.

For all out performance, the aftermarket single four barrel intake manifolds are at the top of the list. There are some specialty manifolds out there in both cast and sheet metal design that permits the use of modern dual four barrel carbs and these add another level of performance to the engines that were single four barrel equipped. The right combination of manifold, carburetor, and carburetor spacer on a well built Y can easily have the horsepower exceeding that 600 number.

CARBURETOR SPACERS

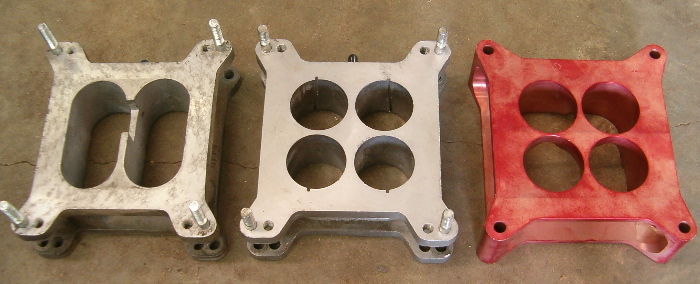

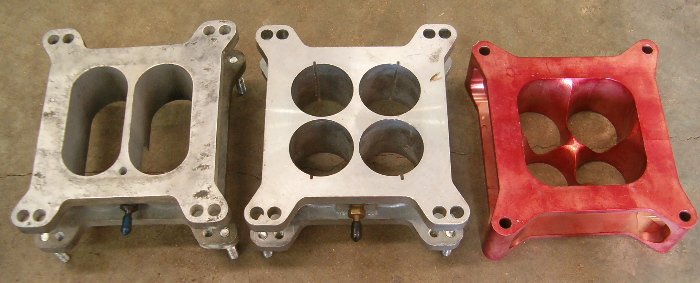

And now that carburetor spacers have been mentioned, here’s some more detail. Different intake manifold designs prefer different designs of spacers to compliment their performance. What works on one particular brand of intake is not necessarily the best for another intake. While I’ve found that the Blue Thunder intakes for the Y prefer what I call a 2” HiFlo spacer, the Mummert intakes seem to do better with a 2” tapered spacer. The HiFlo spacer is four holes on top and transitions to four squares on its bottom. This spacer design tries to maintain more of the dual plane attributes in that the air flow that is directly above the intake manifold is kept separated from side to side. The tapered spacer design (HVH calls this the Super Sucker) starts out as four holes on the top and transitions to a large open cavity on its bottom. This spacer design mimics a single plane design before allowing the air flow to actually enter the intake manifold. I’ll add that the older version BT intake manifolds have a slot in the divider plate while the older Mummert intake did not. A newer version of the Blue Thunder intake (let’s call these version 4 & 5) has eliminated that plenum slot while the latest Mummert dual plane intakes have the slot. Subtle changes like this requires different carb spacer designs. If simply concentrating on low end performance and off idle drivability, then a simple four hole carb spacer provides the best low rpm torque numbers. If going for top end horsepower, then it may take some trial and error experimentation to find that perfect spacer design for a specific engine combination. It is important that the holes in the spacer closely match the throttle bore sizing of the carburetor.

If manifold vacuum attributes are marginal due to the camshaft being on the ‘big’ side or a reduced lobe centerline, then maintaining a true dual plane scenario will be worth an additional 1-1½” Hg of manifold vacuum. When there is a slot in the manifold plenum divider or the carburetor spacer allows an opening or path between the planes, then the side of the intake where the piston is going down and drawing in an intake charge sees a vacuum leak due to a piston on the opposite plane being at TDC having both valves open due to the camshaft overlap cycle.

CARBURETORS

Carburetors in general can be considered simply as just a controlled fuel leak into the engine. The key to a good performing carburetor will center on its ability to atomize the fuel. The better the job it does at atomizing or making the fuel droplets smaller, the better the fuel burn will be within the combustion chamber. Only the surface of a fuel droplet burns so the thought process here is to make more droplets per a given volume of fuel so that there is more surface area available for combustion. Different carburetor manufacturers have different ways to mix air with the fuel in order to accomplish that breakup of the fuel. Some of those systems include air bleeds, emulsion tubes, venturi sizing, and discharge nozzle configurations.

While those older formulas for calculating the maximum carburetor size work fine for a completely stock engine, they are not applicable for carburetor sizing when modifications are performed that increase the air flow within an engine. From an oem standpoint, carburetor sizing for the stock grocery getter engines was kept conservative if for no other reason than to minimize warranty claims by being able keep engines in check in regards to top end and rpm capability. While a stock Ford Y-Block is typically satisfactory with a four-barrel carburetor that has a maximum of 400-500 cfm, any modifications performed such as cubic inch increases, upgraded camshafts, and cylinder head modifications will have the engine being favorable to using larger sized carburetors. There are a multitude of differences in the available carburetors and the internal circuitry and metering will make or break a particular carburetor in its planned use. Carburetor sizing ultimately depends upon how the engine is being used and should be sized accordingly.

This is a good time to bring up double pumper carbs versus vacuum secondary carbs. A double pumper carb or one with mechanical secondaries is very rarely sized correctly for all conditions so with those carburetors it is very easy to go too big. For many applications, it is recommended to use a vacuum secondary carburetor and, in these cases, one should intentionally choose a carburetor that is on the ‘big’ side of what is needed. Because the secondaries on a vacuum secondary carb are demand driven by the amount of air being drawn through the primary barrels, the secondary side of the carb will only open the amount that the engine requires thus making that carburetor perfectly sized in most conditions.

For mildly warmed-over Ford Y engines, vacuum secondary carburetors in the 600cfm range prove to be adequate. When going for 300 or more horsepower, then the vacuum secondary 750 cfm carburetors are better suited assuming the remainder of the engine has been modified accordingly. Keep in mind that the two barrel side of a 750 cfm carb is roughly the same size as many of the factory supplied two barrel carbs so for normal driving, the 750 carb is expected to drive the same once that carb is tuned to the engine that it is installed on. The 365 cubic inch Y that was entered in the 2015 Engine Master Challenge used a 1050 cfm Holley Dominator carburetor thus maximizing the score in that particular competition. A recent Ford Y built by Joe Craine with the new Mummert single plane intake and a 1250 cfm Holley Dominator 4V carb peaked out at 613 HP. For a 630 HP Ford Y that was built at this shop, the total cfm requirement was in excess of 1300 cfm provided by two smaller carbs on a tunnel ram intake manifold. As the air flow requirements for an engine go up, so too is the need for larger carburetors.

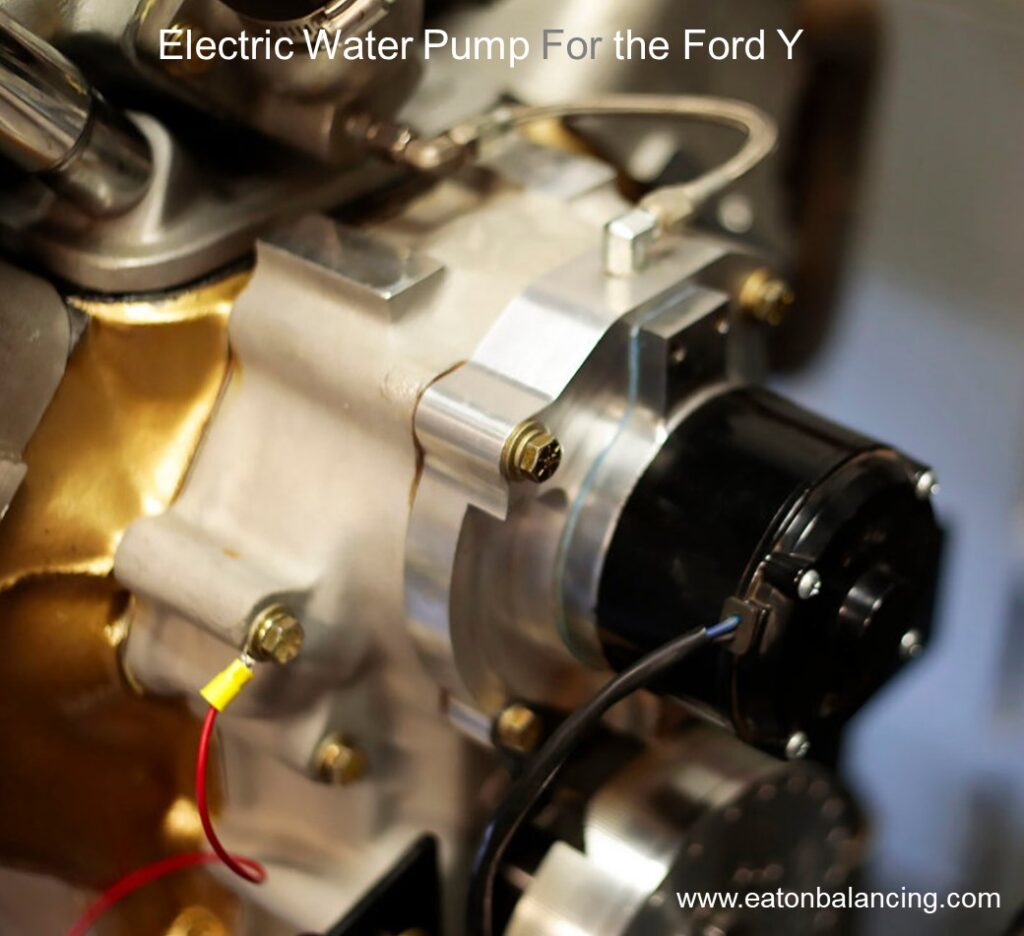

ELECTRIC WATER PUMP

Using a 342” Y that was built for a Bonneville effort as a basis for this test, the mechanical water pump was swapped out for an electric unit. An average of 5 HP was gained over the 3700-7000 rpm test range and the peak horsepower saw a 5½ HP increase. The mechanical pump was already being underdriven by 30% (6.5” w/p pulley and 5” crankshaft pulley) and saw a peak HP value of 534.2. With the change to the electric water pump, that peak HP number jumped up to 539.6 HP. What was interesting on this particular test is that the horsepower gains were not so much percentage based on a given or peak number rpm as it was pretty much the same 5 HP increase throughout the whole rpm test band. Simply said, the addition of an electric water pump was worth 5 HP regardless of the rpm it was tested at. If the water pump and crankshaft pulleys are closer to a 1:1 scenario or those cases where the w/p pulley is actually smaller than the crankshaft driven pulley, then look for an even greater horsepower increase when switching to an electric water pump. Mechanical water pumps can be considered just another horsepower robbing accessory.

IGNITION TIMING

The ignition timing attributes vary as the engine combination changes. The cylinder heads are the main controlling factor in this as combustion chamber design and spark plug location/angles are major keys here. Fuel is another factor and if doing a controlled test, then the fuel itself must be considered. Different fuels have different burn rates and as a result, ignition timing must be modified in which to compensate. As a general rule, as the compression ratio gets lower, then additional ignition spark advance is required to achieve optimum results. In one particular instance during a 500 plus HP Y-Block dyno session where the optimum ignition timing was determined, there was a 7 horsepower decrease in retarding the ignition timing just 1° from value X and a 6 HP decrease in advancing the timing 1° from value X. In making 2° changes in timing and not going to that extra level of detail in nailing down single degrees or half degrees of ignition timing is leaving some potential horsepower on the table. Once an engine is tuned for a specific fuel, then the tune up should be re-evaluated when that fuel is changed to a different brand or octane rating.

CARBURETOR JETTING

While changing the carb jetting is a reasonably simple act by itself, actually determining the correct jetting does become complicated. Some of those tools for determining if the jetting is optimum includes reading the spark plugs, wide band oxygen sensors, and EGT (exhaust gas temperature) readings. But regardless, jetting is a key component to the overall tune up. Several factors can force a jetting change to an engine that was at one time perfectly jetted. While weather or atmospheric conditions is at the top of the list, changing the brand of fuel or simply changing the ignition timing are also players. As the specific gravity of the fuel changes, so too must the jetting. The tuner has to remain cognizant that making a single change to an engines’ tune up very often forces many of the other parameters to be revisited to get the most out of a combination.

MORE TO COME

This concludes part III of a multi-part series on the different items that can be performed on the Ford Y (and most other engines for that matter) in improving both the power and efficiency of those engines. The next article in this series will start off with spark plugs and then in no particular order, will go into other areas of the engine where changes can be made.

Until next time, happy Y motoring. Ted Eaton.

Note: The original plan was for this article to be published in The Y-Block Magazine issue #177. Due to problems arising from the publishing company reorganizing and then relocating, the YBM like so many other publications during the 2015-2022 time frame, simply went out of business.