This is a continuation of a series of articles that goes into the different areas of the engine that can be worked on to increase the power and efficiency of the Ford Y. Keep in mind that many of these also apply to almost all other makes of engines and not just the Ford Y. These topics are in no particular order in regards to their benefits. Some are more beneficial when added or combined with others.

SPARK PLUG GAPS

This area is controversial to say the least. To date, I’ve found no additional horsepower in increasing the spark plug gaps. On the other hand, I have found decreases in horsepower when extending the gaps to the point that the engine misfires in the upper rpm band. As a general rule, the lower compression ratio engines do tolerate wider gaps before that ignition misfiring occurs. Higher compression and carbureted engines prefer spark plug gaps in the 0.035” range and in some instances must be gapped as low as 0.020” – 0.025” depending upon the ignition system being used. Supercharging or boosting an engine also requires much tighter than normal spark gaps. As combustion pressures rise, the voltage requirements at the spark plug also increases which necessitates smaller gaps. When in doubt, stay conservative on the spark plug gaps.

INDEXING AND SIDE GAPPING

And then there’s indexing and side gapping of the spark plug electrodes. To test this, a new set of spark plugs were not side gapped and were intentionally installed with the side electrodes placed in a downward position. The spark plug is essentially trying to fire upwards instead of down. The engine is run like this and the data is captured. Another set of same part number spark plugs are side gapped and indexed in the cylinders so that the side electrode is in the ‘up’ position in the cylinder so that the spark fires downwards or the flame kernel is not being separated or divided by the side electrode. In this case, an increase of 1½ HP is found. That’s technically within the measurement error on this particular round of testing but it’s been done twice now with the same increase both times so let’s call it a gain. These tests were performed on pump gas engines and if performed on a high compression engine requiring race or high-octane fuel, the results would have possibly been more definitive.

SPARK PLUG HEAT RANGE

As a general rule, use as hot as possible spark plug that does not cause any detonation issues or show signs of overheating on the plugs themselves. Running the engine with spark plugs that are too cool does increase the amp loading on the ignition system while also shortening spark plug life. Dyno testing has shown improvements by running hotter spark plugs versus using those that are on the cool side. The hotter plugs burn more cleanly and do a better job in igniting the fuel mixtures. But when trying to determine which spark plug heat range is optimum, start first with the cooler plugs and work your way upwards to the hotter ones.

CRANKSHAFT JOURNAL SIZING

Reducing bearing speed by reducing the crankshaft journal sizes is just another component that’s looked at when going for some additional power. Improved efficiency also comes to the forefront with the reduction in journal sizes as overall friction is reduced. A general rule of thumb for journal sizes is a 2-2½ HP increase for each 0.010” that both the rod and main journals are turned undersize on most V8 engines. Reducing the 312 main journal size to the 292 main size is worth 5-6 HP by itself. For many of the high horsepower builds, my own preference is the standard 292 main journal size along with the 1.889” Honda rod journals. This particular combination of journal sizes has already produced a number of +500 HP Y engines with several of these being pump gas friendly street engines. For the 2019 303” Joe Craine Engine Masters Challenge engine, 0.060” under 292 main journals as well as a 0.010” under Honda rod journal size was used on a stock 292 cast crankshaft. That particular iron headed engine at 10.4:1 compression ratio was making 428 HP on the JE Piston facility dyno at Mentor, Ohio. Those are some very good numbers for a pump gas friendly iron headed 292 Y engine.

PUSHROD LENGTHS

While dyno testing a 318” Y with a set of Mummert aluminum heads, the opportunity arose in which to test the pushrod length scenario in regards to horsepower production. The pushrod lengths on a shaft mounted rocker system helps to determine the final rocker arm ratio simply due to where the adjuster resides in the rocker. As a general rule, the longer pushrod puts the adjuster at a higher point which in turn increases the rocker ratio. For the aluminum headed pump gas 318 Y that was being used as a test case with a set of 1.6:1 (advertised ratio) roller rockers, the peak horsepower value while using an 8.000” effective length pushrod was 416. When switching to a set of 8.100” effective length pushrods, the peak horsepower value jumped up to 423. That’s a 1.7% increase in power. In this case, the increase in push rod length increased the rocker arm ratio but the actual rocker arm geometry itself was not changed. The aluminum heads simply like all the valve lift you can throw at them.

PISTON RINGS

There are two dimensions on the pistons rings to be considered when looking for horsepower advantages. One would be the width or that portion of the ring that actually contacts the cylinder wall while the other is the radial thickness or the depth of the ring going into the piston groove. While the cylinder wall contacting thickness is directly related to the amount of friction that will be present at the cylinder wall, the radial thickness if reduced will also reduce the amount of tension that the ring presents to the cylinder wall. While the original rings for the 312 Y’s were 5/64” & 3/32” thick (0.078” & 0.094” respectively), some of the newer compression rings being used are 1.0mm, 1.2mm, and 1.5mm thick. In the inch format these are 0.039”, 0.047”, & 0.059” thick. Switching to the thin ring design is worth as much as twenty-five horsepower on stock types of rebuilds simply by reducing the cylinder wall drag. When observing the brake specific fuel consumption numbers during dyno testing, lower BSFC (Brake Specific Fuel Consumption) values are observed when using the thinner style piston rings which are strong indicators of reduced friction. Increased power and fuel efficiency are both positive attributes here.

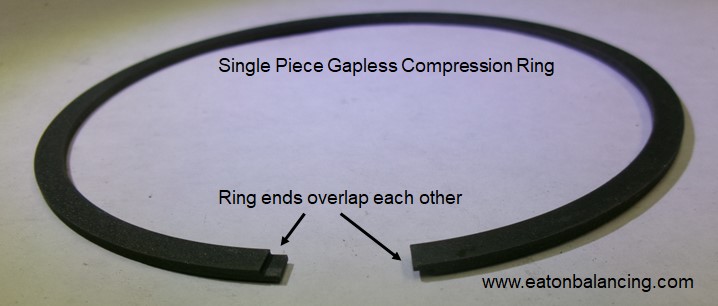

Also not to be left out of this discussion are gapless rings. There are two basic styles for these. One is what I will call the dog leg style where the ends overlap each other.

Childs and Albert Z gap ring

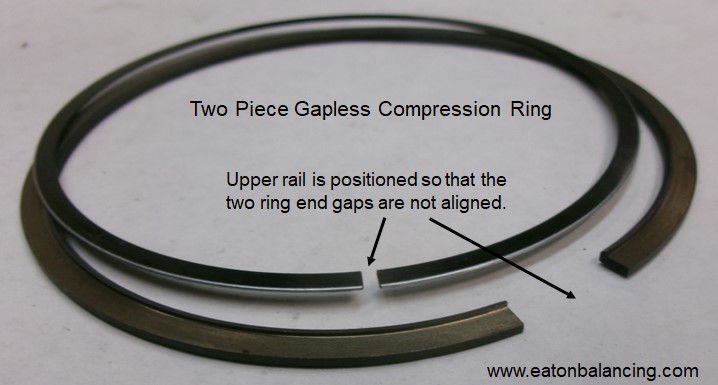

The other is a two-piece style ring where you simply align the two gaps 180° apart from each other to make for a gapless ring.

Total Seal gapless ring

CYLINDER WALL FINISH

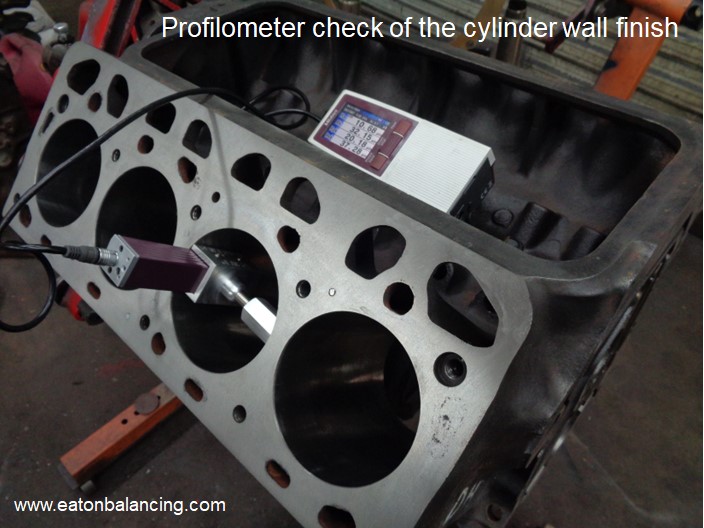

Not to be left out here is the cylinder wall finish. Torque plate honing is always beneficial and more so when the cylinder bores are taken out to the extremes. This simply ensures that the bores are truly round when the cylinder heads are torqued in place.

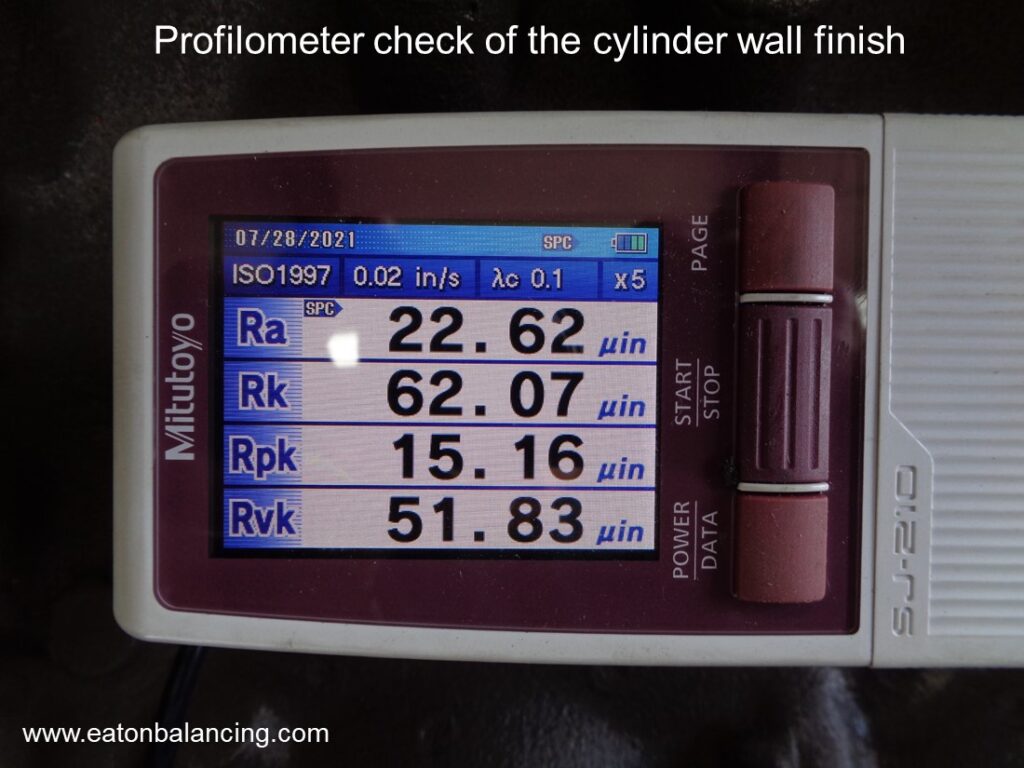

The cylinder wall finish at the completion of honing is also important. It has to be just rough enough to allow the rings to initially seat but not so rough as to create extra friction and wear on the rings. Doing what is termed a plateau finish is where finer grit stones or brushes are progressively used to knock the peaks off of the tops of the grooves made by the rougher stones. This still permits those deeper valleys in the grooves to remain so they can retain the oil necessary to keep friction at bay. Appearances can be deceiving when just looking at a hone finish but measuring those finishes with a profilometer can give a definitive number to those finishes. For different rings and or applications, there are specific targets for the cylinder wall finish.

While a cylinder wall finish being measured with a Mitutoyo Profilometer gave Rpk and Rvk values of 11.5 and 23.9 (values that are typically considered to be more than adequate for the 1.2mm rings being used in a particular Ford Y build), a finer finish did net a power increase. In refinishing the cylinders to Rpk and Rvk values of 7.0 and 23.7 respectively but with all other parameters being identical, this allowed for an increase of 5HP over the previous values. The example stated here was a 326 CID Ford Y that initially netted 393HP/384TQ. With the finer finish, the engine power numbers increased to 398HP/388TQ. This was another pump gas friendly Ford Y but gives an excellent example of how cylinder finish can be manipulated to help the power numbers. Fuel efficiency is also increased as the BSFC numbers are also reduced.

RING END GAPS

Part of any engine assembly includes at least checking the piston ring end gaps. The primary reason for this is to ensure an adequate gap that will not be closing in on itself when hot and in turn creates an extra drag on the cylinder walls and/or damage to the piston ring lands. The key here is to have a piston ring end gap that will not completely close up but also a gap that is not excessively large which would otherwise permit some of the combustion pressure to escape past the rings. If targeting for a specific gap value, then always err to the loose side of spec as no good ever comes from erring to the tight side.

The old school of thought was 0.004” gap per inch of bore for the top piston rings and 0.003” gap per inch of bore for the second groove rings. More recent testing has shown that having the second ring end gaps the same or even larger than the top ring gaps increases the power potential on high performance engines. This comes about due to the pressure that builds up between the top and second rings thus unseating the rings; by increasing the second ring end gap, that pressure can be relieved. This makes more sense by realizing that the second ring is more of an oil control ring than an actual compression ring. Back in the days when Nascar used a separate engine for qualifying, those pistons only had one compression ring and an oil control ring but no second ring. Eliminating the second ring removed an additional friction point within the engine.

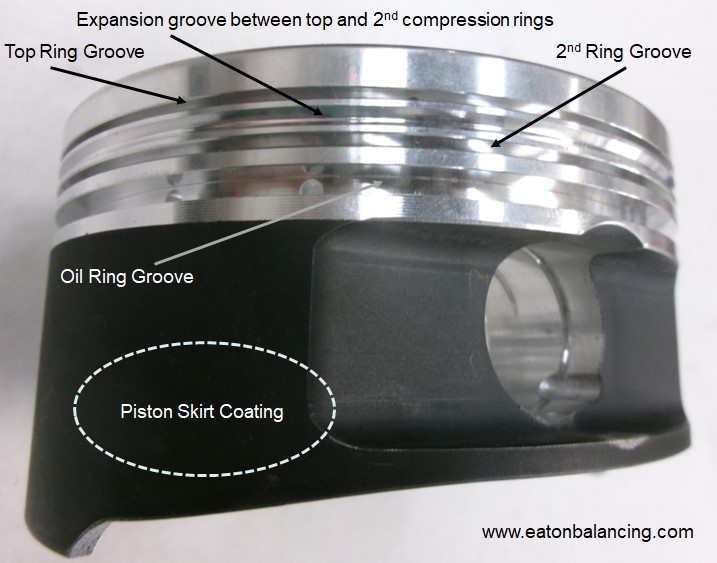

Another option is an expansion groove between the top and second rings to give some of the pressure that builds up a place to expand within rather than unseat the rings. While many custom pistons have this option already included, it’s always a good idea to see that it’s actually there. It is beneficial.

ENGINE OIL

Not all engine oil is created equal and that’s by design. Simply said, there are different oils for different applications.

Two different Ford Y engines on the dyno saw major differences in the peak horsepower numbers when comparing dyno results using 10W-40 oil versus 20W-50 oil. A 570+ HP 352” Y engine saw a 10 HP increase while a 320 HP 322” Y (the dyno mule) saw an 8 HP increase when switching from the higher viscosity oil to the lower viscosity oil. In both of these tests, both the coolant and oil temperatures were kept constant. A very extensive oil test using the 312 dyno mule showed only a 2-3 HP difference between 0W-20 oils and 10W-40 oils but when that oil viscosity is increased to 20W-50, there’s a major drop in power numbers.

While I find no big changes in performance between conventional and synthetic oil blends when the viscosities are the same, there are some other observations that do come to the forefront. Oil temperature and oil viscosity are two such players. Hotter oil simply makes more power and that’s a result of the oil viscosity and/or the shear aspect reducing as the oil temperature goes up. The rated oil viscosity is a major player also. As the viscosity rating goes up, the horsepower numbers go down. This is simply a result of more loading on the oil pump and additional shear imparted on the bearings as the oil viscosity increases. In this instance, consider the oil pump another horsepower robbing accessory.

But decreasing the oil viscosity to increase the horsepower is treading on thin ice if not taking into account the particular clearances within an engine. In short, the engine must be built to tighter clearances if planning on using engine oil with reduced viscosity attributes. Flat tappet camshafts also require a given amount of oil shear in which to promote lifter rotation so be cautious in some of the lower viscosity rated oils being used in the Y family of engines. My own preference is to not use any oil with a rating of less than 30W within its viscosity rating for engines with flat tappet camshafts. In this case 10W-30 oil would be okay but 5W-20 would not.

COATINGS

A variety of coatings are now available for the various engine components. Friction coatings for the piston skirts and ceramic coatings for the piston tops have their advantages. Also available for both the camshaft, connecting rod, and main bearings are various coatings to reduce friction at those points. All these coatings come with a price tag so the costs for these must be weighed against the application they are being used for to determine if they are going to be cost effective.

MORE TO COME

This concludes part IV of a multi-part series on the different items that can be performed on the Ford Y (and most other engines for that matter) in improving both the power and efficiency of those engines. The next article in this series will start off with blueprinting and then in no particular order, will go into other areas of the engine where changes can be made.

Until next time, happy Y motoring. Ted Eaton.

Note: The original plan was for this article to be published in The Y-Block Magazine issue #178. Due to problems arising from the publishing company reorganizing and then relocating, the YBM like so many other publications during the 2015-2022 time frame, simply went out of business.