In the course of dyno testing various Ford Y-Block engine combinations, there have been a number of items tested that by themselves did not necessarily account for big horsepower gains but when added together do add up for a significant increase. Included in this list would be exhaust systems in general, upgrading to higher ratio rocker arms, harmonic damper design, crankcase ventilation and/or air evacuation, electric water pumps, oil pan modifications, cylinder head modifications or upgrades, intake manifolds, carburetion, and carburetor spacers to name just a few. I’ll add that in many instances where the power is being increased, the efficiency of the engine is also being improved; be sure to look at some of these modifications being suitable also for fuel economy increases.

The test engine that continues to generate a majority of this information is a +060 over Ford/Mercury 312 Y-Block. The camshaft being used is an older Crower Monarch grind with 238°@0.050” duration that’s ground on 110° lobe centers and is installed with 2° of cam advance (108° intake lobe center line). The well used replacement cast flat top pistons are sitting 0.025” in the hole and use the older technology wide rings for cylinder wall sealing. Since that first day of being put on the DTS dynameter to do baseline dyno testing for the 2009 Engine Masters Challenge Ford Y engine entry, this engine has thus far seen over twenty five different pairs of heads, over two dozen different exhaust systems in a myriad of configurations, different dampers, five different sets of rocker arms, a variety of pushrod lengths, thirteen different 3X2 intakes, twenty plus dual quad setups, over a dozen different single four intakes, two different oil pans, over three dozen different carburetors on the single four barrel setups (carbs on dual quad setups or three deuce setups are not included in this count), and carburetor spacers too numerous to count.

At the time of this writing (Sep 2025), that dyno mule has over 1100 dyno pulls and that engine (without being freshened up) was also used in a ’32 Ford Coupe that made a pair of cross-country trips from New York to the Bonneville Salt Flats and back. 11K+ miles on that engine during the course of also being used as dyno mule for parts testing purposes and all with the same bearings and rings. Prior to 2008, this engine was originally in Bob Martin’s ’55 Mercury which became a core engine when a new Ford Y engine was put together for Bob’s Merc.

There is no particular order to all the topics presented here. Some of these are worth more power than others while some of these modifications or changes are more beneficial when combined with others. In the end, it’s the overall combination of parts that makes all the difference.

ROCKER ARMS

Rocker arm testing on the 312 dyno mule with stock ECZ-G heads showed that increasing the ratio from 1.4:1 to 1.54:1 was worth 3 HP in peak values. Switching again from 1.54:1 to 1.6:1 was worth another 3 HP. There were no measurable power differences between the Dove, Harland Sharp, and Rocker Arm Specialist 1.6:1 roller rocker arms when all testing variables were kept constant. Rocker arm weight does not appear to be a variable that makes a performance difference in this particular testing instance. Had the valve springs been marginal in their set up pressures, then the rocker arm weights might have been an issue. The base peak HP was 267 with the 1.4:1 rockers, 270 HP with the 1.54:1 rocker arms, and 273 HP with the 1.6:1 roller rockers. This particular round of testing was performed on the 312 dyno mule with the Edelbrock #573 3X2 intake with Stromberg 97’s and a set of stock unported and unposted ‘small letter’ G heads. In this test, consider the 1.54 rockers being worth a 1.1% gain over stock while the 1.6 rockers would be a 2.2% gain over stock 1.4’s.

Those horsepower numbers go to the wayside when the rocker arm testing is performed on the Mummert aluminum cylinder heads. Here are those results. Switching from the 1.54:1 OEM rockers to the 1.6:1 roller rockers saw a gain of 12 HP. That’s pretty significant. If you are dealing with ported iron heads, then look for much more than a 3 HP gain as better breathing heads simply responds more favorably to rocker arm ratio increases.

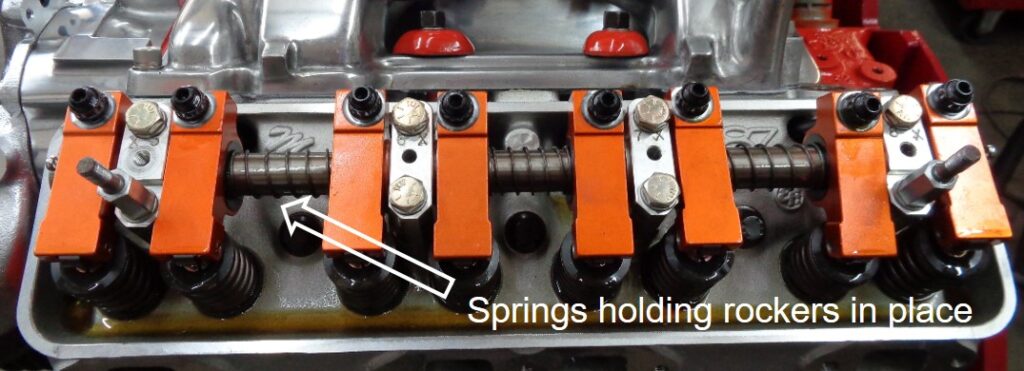

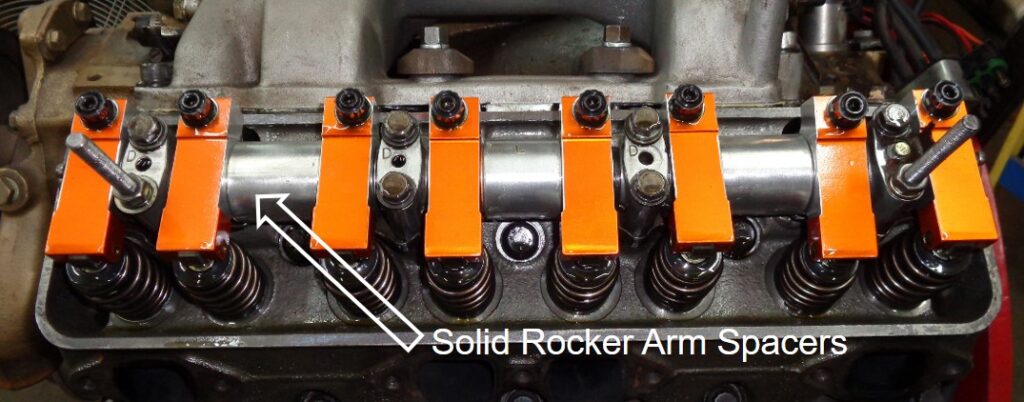

And on the shaft mounted rocker arms, a common hot-rodding practice has been to replace the springs that hold the rockers in place with some form of machined bushings to maintain the rocker arms in their respective positions. Upon dyno testing two different engines on the dyno that had the springs replaced with machined bushings, both engines lost 2½ horsepower. Keeping the bounce or free movement minimal with rocker arm shaft springs does appear to be an advantage in lieu of using some form of machined bushings in their place. I would surmise that the springs act as a dampener to keep ‘free’ rocker arm movement minimal on those camshafts that requires a lash adjustment.

EXHAUST

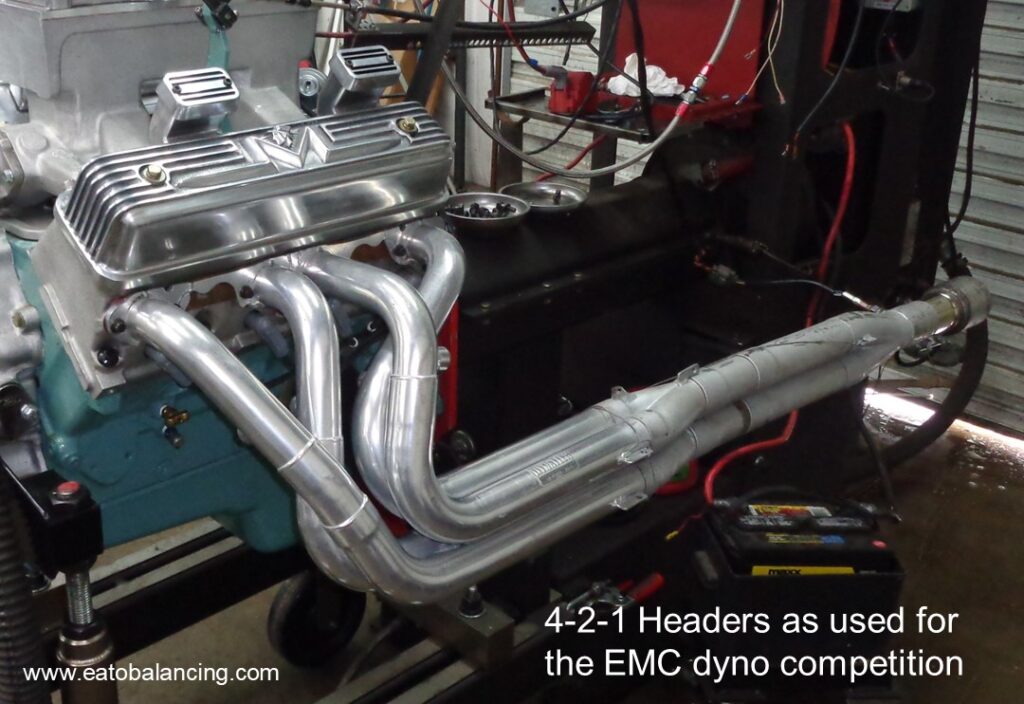

The most obvious upgrade to a single exhaust equipped vehicle is to simply put dual exhausts on it. The single exhaust setup with the overhead crossover pipe on the dyno mule engine with what I’ll call stage I ported heads peaked out at 239 HP both with and without the muffler in place. Using the 1956 exhaust manifolds with dual exhaust pipes and mufflers upped this value to 265 HP and changing those out to the 1957 exhaust manifolds increased this value to 271 HP, also with mufflers. A multitude of headers were tested and one set with mufflers netted a best peak value of 310 HP while a different set without mufflers netted 311 HP. In this series of tests, all engine variables were kept constant including a pair of mildly ported ECZ-G heads (bowl blending with a light de-flash in the ports), stock Mummert intake manifold, a 750cfm vacuum secondary Holley carb, and a set of 1.6:1 Harland Sharp roller rocker arms. Using the single exhaust as the base line, swapping out to the 1956 manifolds saw an 11% increase in peak HP numbers whereas using the ’57 exhaust manifolds was a 13% increase over the single exhaust. The best headers tested with mufflers improved the HP numbers by 30% over the single exhaust. That’s a big WOW!

But let’s take this a step further. In testing a particular 375” Y-Block combination, less than optimum exhaust temperatures were being recorded during the dyno pulls while the fuel mixture readings at both the wide band oxygen sensors and spark plugs were spot on. This particular combination was making 544 HP. Once it was figured out that the cool exhaust temperatures were in part the result of some extremely good scavenging taking place within the headers, the engine combination was changed up to allow the use of a 6.300” long connecting rod (0.450” shorter than the 6.750” rod that was being used) and a camshaft that has four more degrees lobe centerline angle built in. This allowed for less residence time for the piston at top dead center and a reduced camshaft overlap cycle. As a result, there is a smaller amount of fuel mixture going out the headers during the overlap cycle but still enough overlap to be beneficial for the intake charge to get jump started prior to the piston actually moving down. These two changes alone upped the horsepower to 581. The lesson here is to take the whole combination into account and this includes the exhaust system which is very often overlooked.

CRANKCASE VENTILATION

And how much are additional breathers on the valve covers worth? The test engine for this was a 343 cubic inch Y race engine and was tested with the one breather at the front of the valley cover versus valve covers that each had two additional breathers thus putting the total to five for that test. With one breather, the engine peaked at 497.6 HP and with five breathers, that same engine peaked at 500.4 HP. That 2.8 HP increase is a 0.5% improvement. By itself, that percent value doesn’t sound like a big number but in my Y powered roadster that would be almost 3 hundredths of a second improvement in a quarter mile race. Don’t discount those little improvements. They’re all slowly adding up.

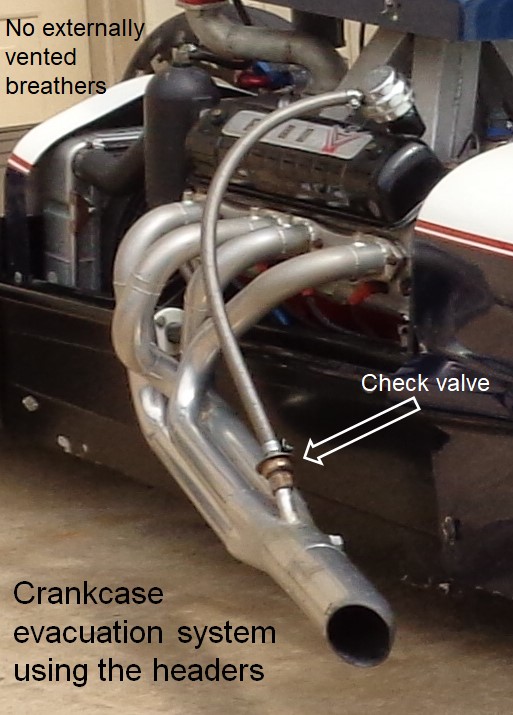

CRANKCASE EVACUATION

During the exhaust testing, the Eaton Balancing ‘23T roadster headers were also tested with and without the pan evacuation system. Also referred to as a crankcase evacuation system. This particular pan evacuation system is powered by exhaust flow generated within the header collectors and when used on the race engine, the crankcase is essentially sealed up so that a slight vacuum can be generated in the crankcase of the engine. Using the roadster headers on the 312 dyno mule with stage I ported heads and with a five breather setup, the engine peaked at 307.4 HP without utilizing the pan evacuation system. Changing out the valve covers to a sealed set and sealing up the valley breather hole netted 308.9 HP with the pan evacuation system hooked up and functioning. In this particular instance the pan evacuation system is worth another 0.5% HP. Add this to what was found with using additional breathers over a minimal breathing crankcase system and the pan evacuation system is expected to be worth a full one percent improvement over running a single breather opening.

IGNITION

Dyno testing a myriad of distributors finds no horsepower advantages as long as the same total timing value and other test variables are consistently maintained. Tested to date have been stock distributors, Mallory, Grant Flamethrowers, MSD, TSP, CRT, magnetos, distributors that look like magnetos but are electronic in nature, and an assortment of ignition boxes. It was initially believed that a magneto might actually cost some power due to the internal magnet drive on those but even in that instance, the mag made the same power as the other ignition systems. The engine really does not care what drives the spark as long as that spark is sufficient and arrives at the right time. The plus side to an electronic distributor versus a breaker points style ignition would be the spark plug life. Almost infinite plug life with an electronic distributor versus what you would see with a breaker points distributor.

MORE TO COME

This concludes part I of a multi-part series on the different items that can be performed on the Ford Y (and most other engines for that matter) in improving both the power and efficiency of those engines. The next article in this series will start off with harmonic dampers and then in no particular order, will go into other areas of the engine where changes can be made.

Until next time, happy Y motoring. Ted Eaton.

Note: The original plan was for this article to be published in The Y-Block Magazine issue #175. Due to problems arising from the publishing company reorganizing and then relocating, the YBM like so many other publications during the 2015-2022 time frame, simply went out of business.